Table of Contents

Water Spraying Fish Glazing Ice Covering Machine

The Water Spraying Fish Glazing Ice Covering Machine is a specialized equipment used in the food processing industry to improve the preservation and presentation of seafood products. This machine is designed to apply a thin layer of ice glaze on fish or other seafood items to protect them from dehydration, freezer burn, and oxidation during storage and transportation.

One of the key features of the Water Spraying Fish Glazing Ice Covering Machine is its ability to evenly spray a fine mist of cold water over the seafood products. This process helps in quickly forming a protective layer of ice glaze that locks in the freshness and natural moisture of the fish, extending its shelf life and maintaining its quality.

Moreover, the Water Spraying Fish Glazing Ice Covering Machine is equipped with adjustable settings to control the thickness of the ice glaze layer applied on the seafood products. This customization capability allows food manufacturers and processors to meet specific requirements and standards for different types of seafood products, ensuring consistent quality and appearance.

Operation and Maintenance

Operating the Water Spraying Fish Glazing Ice Covering Machine is straightforward and user-friendly. The machine typically comes with an intuitive control panel that allows operators to adjust settings such as water flow rate, glaze thickness, and conveyor speed easily. Regular maintenance of the machine, including cleaning and sanitizing the components, is essential to ensure optimal performance and hygiene standards.

| Serial No. | Options |

| 1 | Fish processing device |

| 2 | Fish cleaning machine scaling |

| 3 | Fish fillet machine automatic |

| 4 | Fish cutting machinery |

| 5 | Fish skin removing machine |

| 6 | Fish washing device |

| 7 | Fish Glazing Ice Machine |

| 8 | Automatic fish cleaning gutting machine |

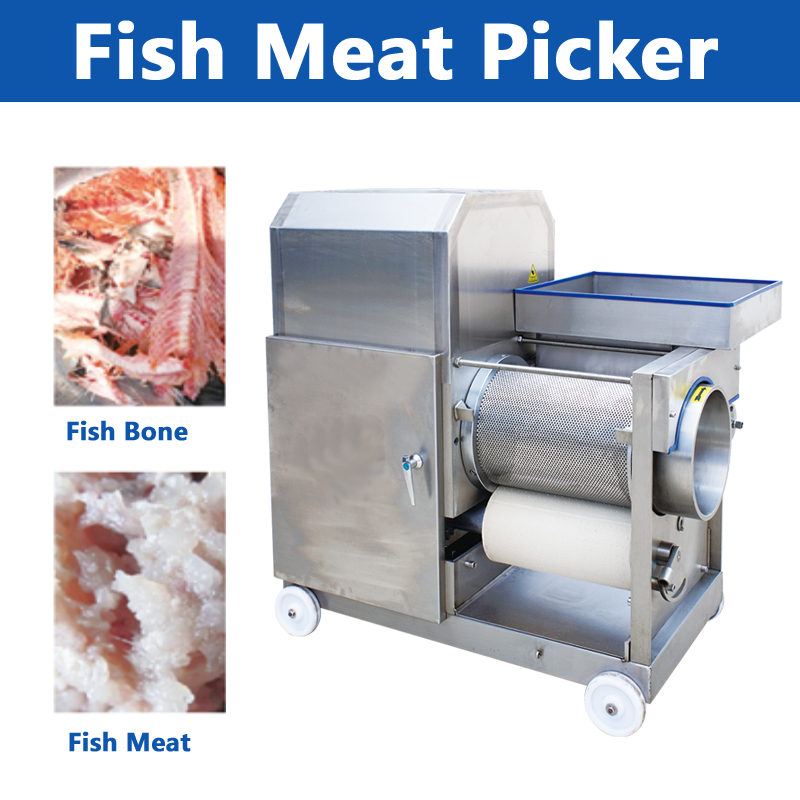

| 9 | Fish meat picker |

| 10 | Fish slicer machine cutting |

It is recommended to follow the manufacturer’s guidelines for routine maintenance tasks and cleaning procedures to prevent any contamination or cross-contamination of seafood products. Additionally, regular inspection of the machine parts, such as spray nozzles, conveyor belts, and water filtration systems, can help identify any issues early on and prevent downtime during production.

Proper maintenance of the Water Spraying Fish Glazing Ice Covering Machine not only ensures the longevity of the equipment but also contributes to the overall safety and quality of the processed seafood products. By adhering to maintenance schedules and best practices, food manufacturers can uphold hygiene standards, comply with regulations, and deliver superior seafood products to consumers.